Snack Food Processing

Our technology offers flexibility in your production process. A rich range of options ensures that you can go along with every new idea or taste. Good crisps have the right ‘cracking’, size, color, taste, and freshness. Dynamech Engineers enable you to develop and produce a wide variety of chips with a constant quality guarantee. balanced engineering and user-friendliness enables you to deliver a top product every day. All of our Snack Food Processing lines can be tailor made to suit your production capacity, from Batch production all the way up to Semi-Automatic and Fully-Automatic lines.

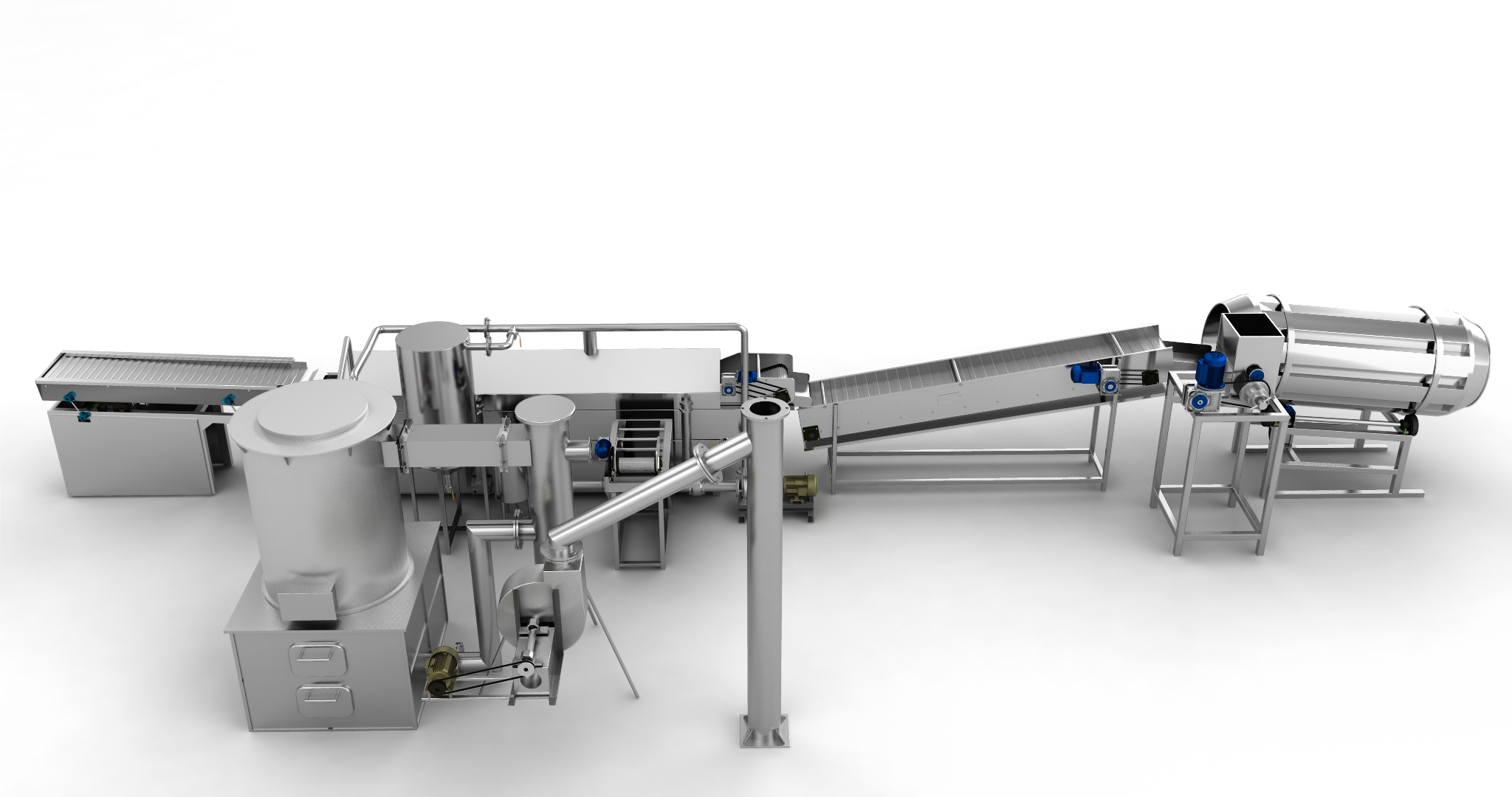

Banana & Cassava Chips

An exclusive line for producing superior quality Banana / Plantain / Cassava Chips. Continuous Frying System exclusively, designed for Banana Chips to achieve maximum product quality and operational flexibility. All of our Snack Food Processing lines can be tailor made to suit your production capacity, from Batch production all the way up to Semi-Automatic and Fully-Automatic lines.

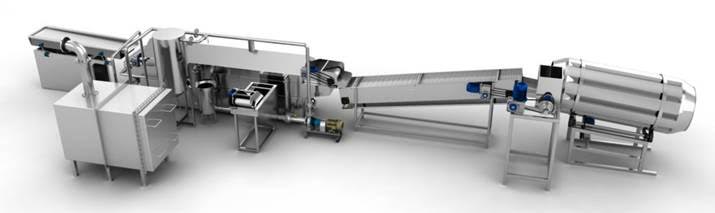

Namkeen & Chevdo

We offer a complete range of solutions for namkeen snacks, also known as Indian savories. Advanced automation improves productivity and therefore savings in your operations. All of our Snack Food Processing lines can be tailor made to suit your production capacity, from Batch production all the way up to Semi-Automatic and Fully-Automatic lines.

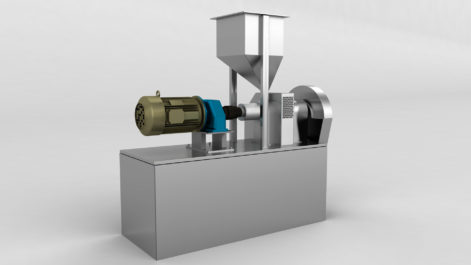

Extruded Snacks

The extruder line incorporates state of the art technology complete with design and technical support; modifications are incorporated to suit local production conditions. All of our Snack Food Processing lines can be tailor made to suit your production capacity, from Batch production all the way up to Semi-Automatic and Fully-Automatic lines.

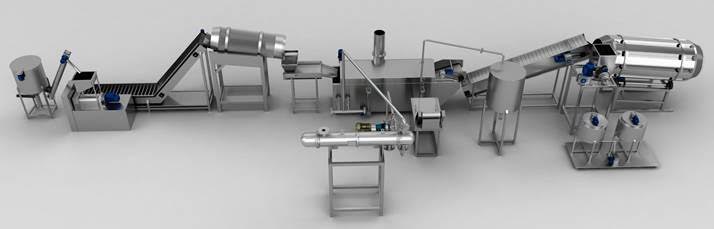

Frying Systems

Our frying systems are ideal for use in restaurants and commercial applications, for both high capacity and entry-level production.

In the Automatic Frying System, the product is fed from one end and it comes out fried from the other end by a conveyor system and deep fried with submerged conveyor. The Automatic Frying system varies with the product category: potato chips has its own unique frying system, and pellets and extruded snacks employ a different system. By understanding such product behavior, we have divided the products into two categories, floating and another non-floating. This fryer is based on an oil circulation system, where the edible oil is heated through a heat exchanger. Pneumatic hood lifting provides easy access for cleaning beneath the fryer. Overall fuel efficiency can increase up to 30-40% compared to traditional systems.

Our Batch Frying Systems are highly efficient as a certain volume of food product is loaded into a frying vessel and stirred for a predetermined time period, and then removed and as quickly as possible. Thereafter the next batch is loaded.

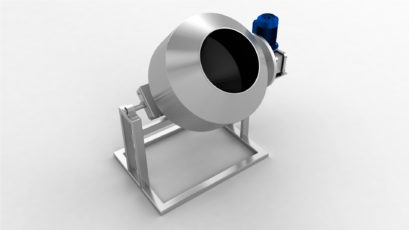

Seasoning & Flavouring Systems

Seasoning is a process of evenly applying flavor to a finished product. We offer both batch and automatic flavouring to meet your capacity & production requirements.

Request a Quote

A Uchumi Quick Suppliers Ltd representative will walk you through our service options.

Download Brochure